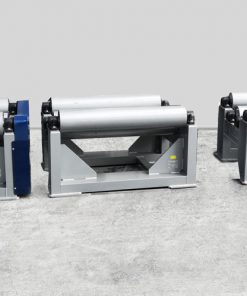

Heavy duty roller

The Idrojet, always attentive to the needs of the market, has developed different types of heavy duty rollers that vary in number of components and capacity.

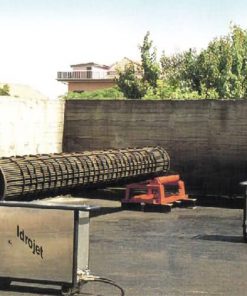

During the external cleaning process of a heat exchanger, whatever type of robot you are using (external / internal), you will still need it, for a thorough and uniform cleaning, of tube bundle rollers that allow the tube bundle to rotate.

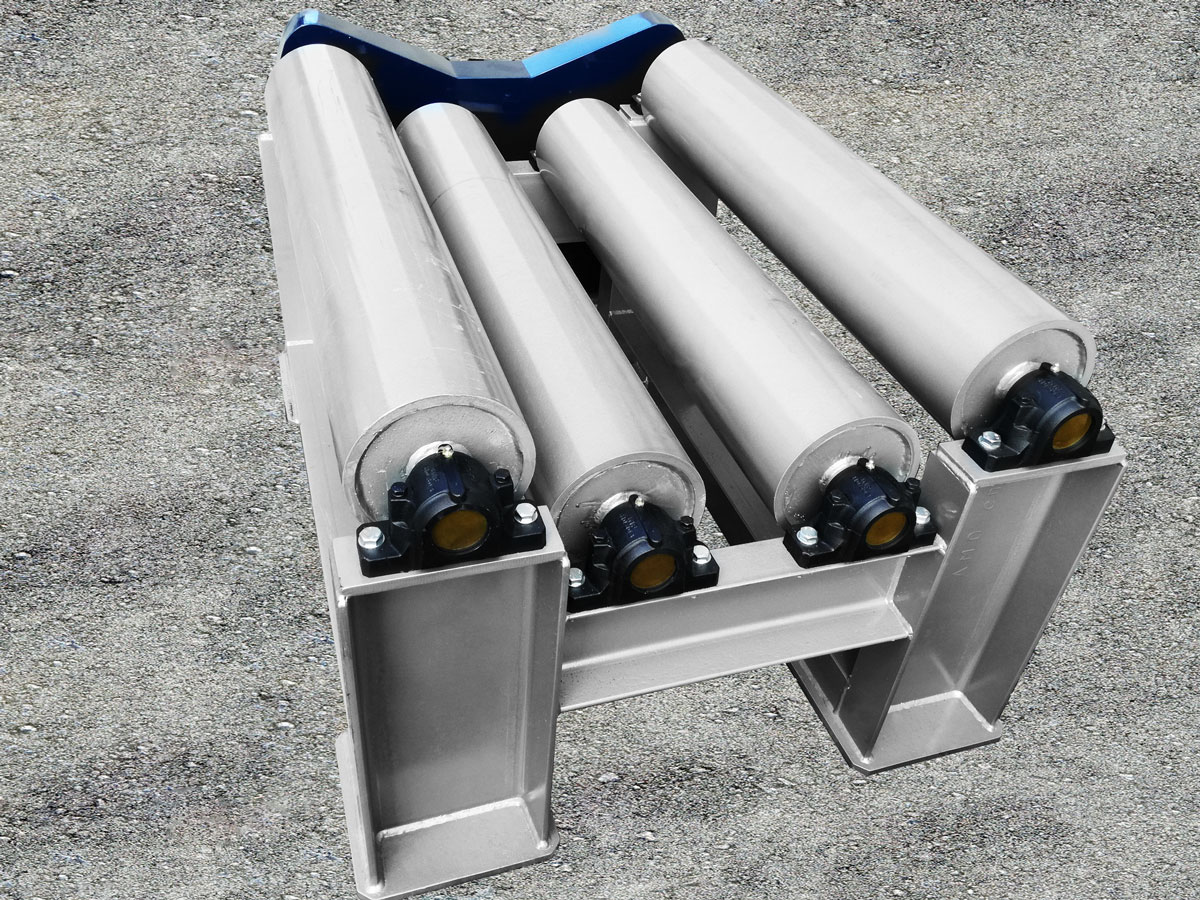

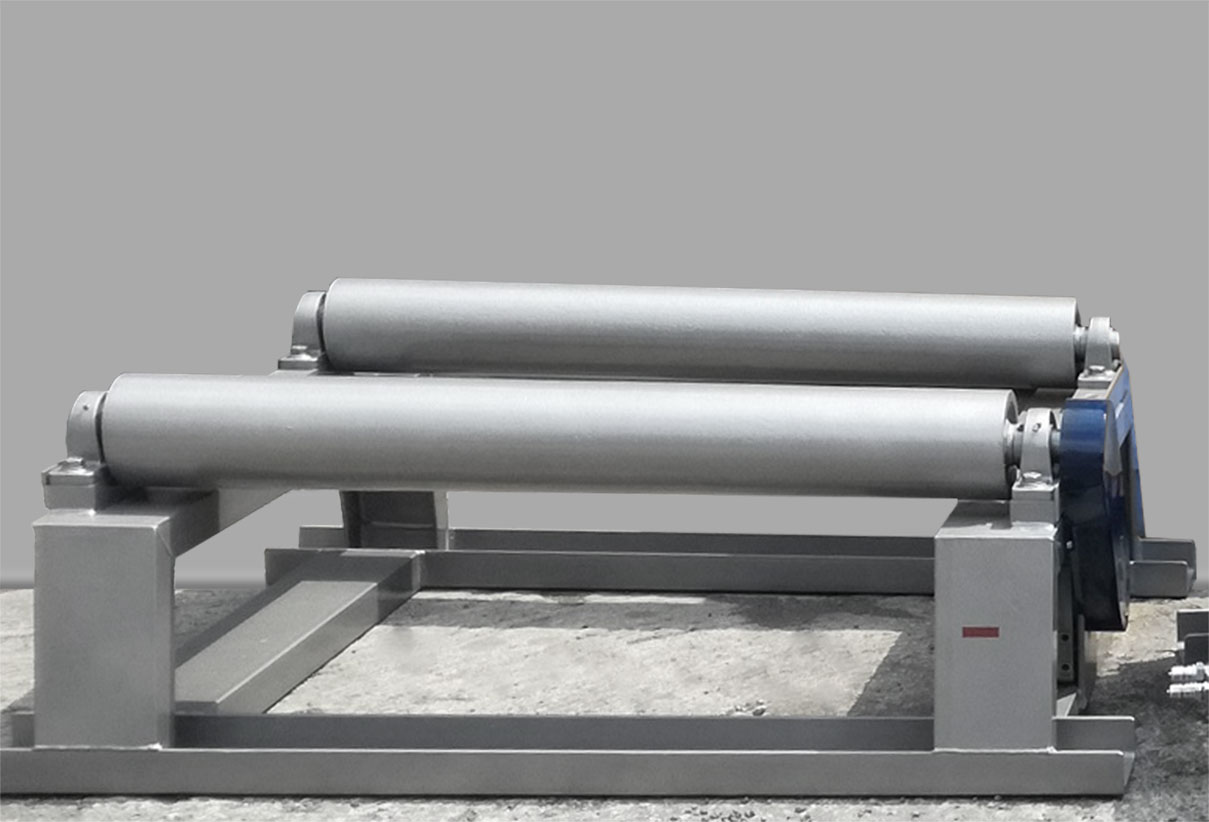

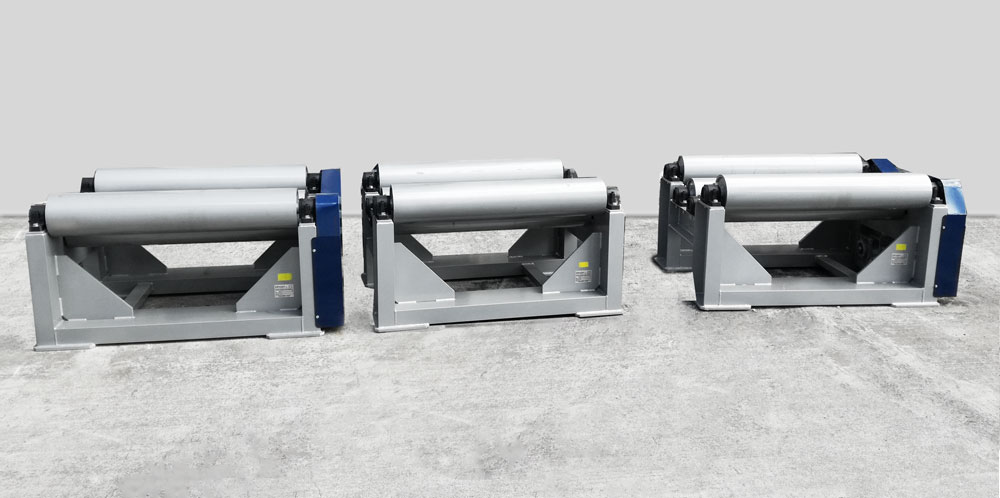

Haevy duty rollers are available in sets of 2 or 3 modules and 2 to 4 rollers, each set consists of a motorized roller unit and a roller unit unguided (idle), the system is hydraulically driven from the i-930 and e-930 robot cab.

Moreover Idrojet has developed some versions of tube bundle rollers with adjustable rollers, to be able to adapt the roller module to the tube bundle, and a synchronized version that allows to rotate heavier tube bundles with ease, providing the set of with 2 or 3 motorized and synchronized modules.

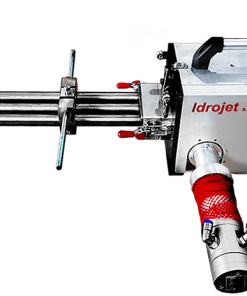

Heavy duty rollers features

- The rollers are driven by a hydraulic motor

- Possibility to adjust the distance between the rollers (only adjustable mod) for rollers up to 35t.

- The drive chain is positioned so that the tube bundle can protrude without compromising the chain itself.

- The bearings mounted on each side of the rollers have a capacity of 50T each, and are also covered by a fairing to avoid damage and keep the bearings clean.

- Total cleaning of the exchanger shell.

The heavy duty rollers developed by Idrojet are:

- 25t 2 modules with 2 rollers

- 35t 2 modules with 2 rollers

- 50t 2 or 3 modules with 4 rollers